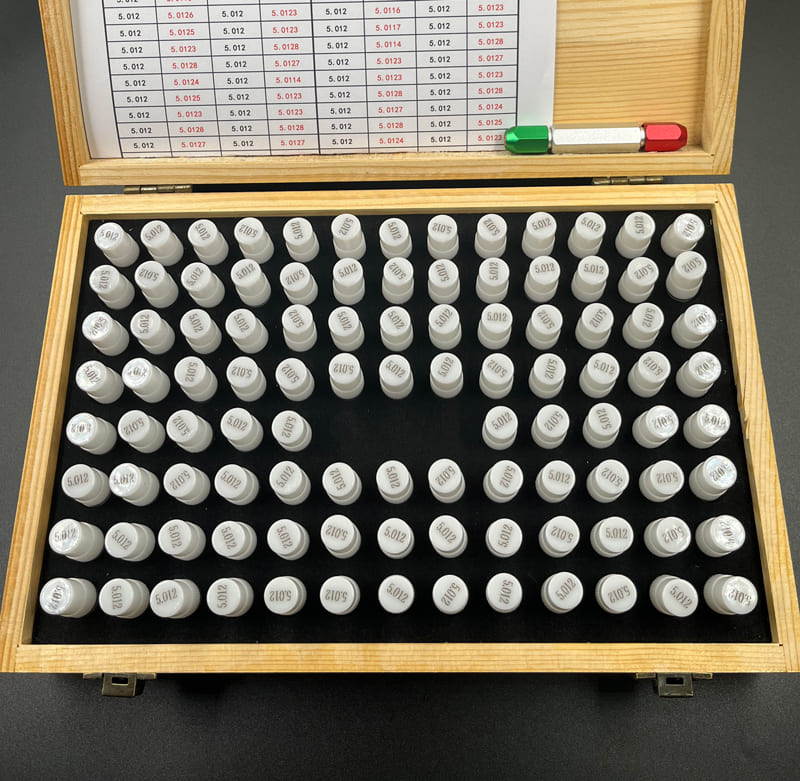

Models of Ceramic Pin Gauge Set

| Model No. | Range | Step | Quantity (pcs) | Tolerance(μin)

Class-XX | Tolerance(μin)

Class-X | Tolerance(μin)

Class-Y | Tolerance(μin)

Class-Z | Tolerance(μin)

Class-ZZ |

| M0+ | .012-.060" | 0.001" | 49 | 0 ~ +20 | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M0- | .012-.060" | 0.001" | 49 | -20 ~ 0 | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M05+ | .0125-.0605" | 0.001" | 49 | 0 ~ +20 | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M05- | .0125-.0605" | 0.001" | 49 | -20 ~ 0 | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M1+ | .061-.250" | 0.001" | 190 | 0 ~ +20 | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M1- | .061-.250" | 0.001" | 190 | -20 ~ 0 | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M15+ | .0615-.2505" | 0.001" | 190 | 0 ~ +20 | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M15- | .0615-.2505" | 0.001" | 190 | -20 ~ 0 | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M2+ | .251-.500" | 0.001" | 250 | 0 ~ +20 | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M2- | .251-.500" | 0.001" | 250 | -20 ~ 0 | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M3+ | .501-.625" | 0.001" | 125 | / | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M3- | .501-.625" | 0.001" | 125 | / | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M4+ | .626-.750" | 0.001" | 125 | / | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M4- | .626-.750" | 0.001" | 125 | / | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M5+ | .751-.832" | 0.001" | 82 | / | 0 ~ +40 | 0 ~ +70 | 0 ~ +100 | 0 ~ +200 |

| M5- | .751-.832" | 0.001" | 82 | / | -40 ~ 0 | -70 ~ 0 | -100 ~ 0 | -200 ~ 0 |

| M6+ | .833-.916" | 0.001" | 84 | / | / | / | 0 ~ +120 | 0 ~ +240 |

| M6- | .833-.916" | 0.001" | 84 | / | / | / | -120 ~ 0 | -240 ~ 0 |

| M7+ | .917-1.000" | 0.001" | 84 | / | / | / | 0 ~ +120 | 0 ~ +240 |

| M7- | .917-1.000" | 0.001" | 84 | / | / | / | -120 ~ 0 | -240 ~ 0 |

Grade XX and Grade X pin gages: They have extremely high precision and a very small tolerance range, and are typically applied in fields such as ultra-precise measurement, calibration, scientific research, and precision experiments.

Grade Y/Grade Z/Grade ZZ pin gages: They are capable of meeting the requirements of the vast majority of precision manufacturing, quality control, and measurement tasks.

If the above models fail to cover your requirements, don’t worry.

Click Here to get an accurate quotation.