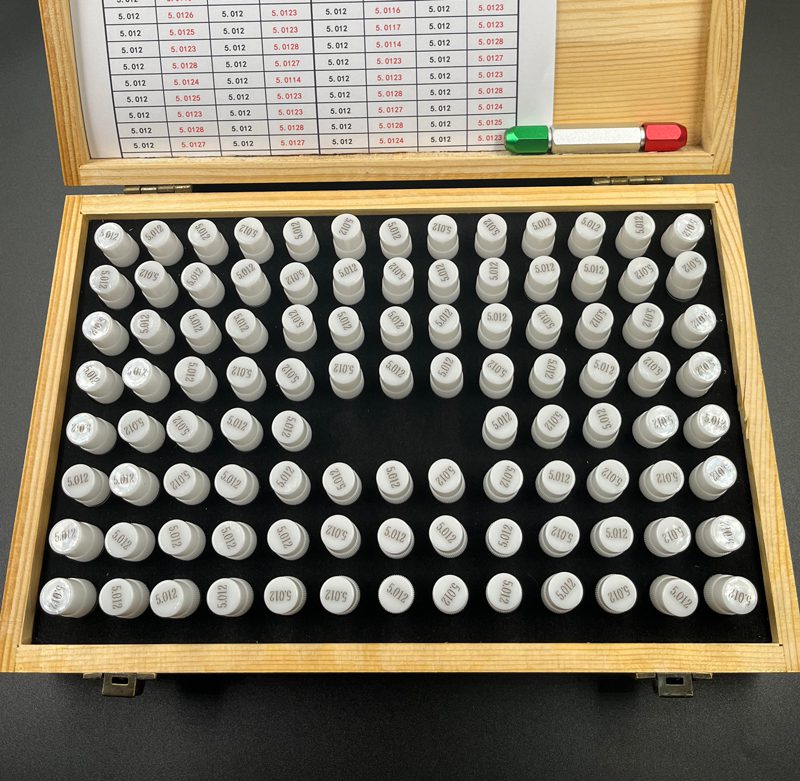

Models of Steel Pin Gauge Set

| Model No. | Range(mm) | Step(mm) | Quantity (pcs) | Tolerance(μm)

Level-0 | Tolerance(μm)

Level-1 |

| HPG-1 | 0.10, 0.11……1.00 | 0.01 | 91 | ±1.0 | ±2.0 |

| HPG-2 | 1.00, 1.01……2.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-3 | 2.00, 2.01……3.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-4 | 3.00, 3.01……4.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-5 | 4.00, 4.01……5.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-6 | 5.00, 5.01……6.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-7 | 6.00, 6.01……7.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-8 | 7.00, 7.01……8.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-9 | 8.00, 8.01……9.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-10 | 9.00, 9.01……10.00 | 0.01 | 101 | ±1.0 | ±2.0 |

| HPG-11A | 10.00, 10.01……10.50 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-11B | 10.50, 10.51……11.00 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-12A | 11.00, 11.01……11.50 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-12B | 11.50, 10.51……12.00 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-13A | 12.00, 12.01……12.50 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-13B | 12.50, 12.51……13.00 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-14A | 13.00, 13.01……13.50 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-14B | 13.50, 13.51……14.00 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-15A | 14.00, 14.01……14.50 | 0.01 | 51 | ±1.0 | ±2.0 |

| HPG-15B | 14.50, 14.51……15.00 | 0.01 | 51 | ±1.0 | ±2.0 |

Level K and level 00 pin gages: They have extremely high precision and a very small tolerance range, and are usually used in fields such as ultra-precise measurement, calibration, scientific research, and precision experiments.

level 0 and level 1 pin gages: They can meet the needs of the vast majority of precision manufacturing, quality control, and measurement work. Among them, Grade 0 is a more widely applied grade.

If the above models fail to cover your requirements, don’t worry.

Click Here to get an accurate quotation.