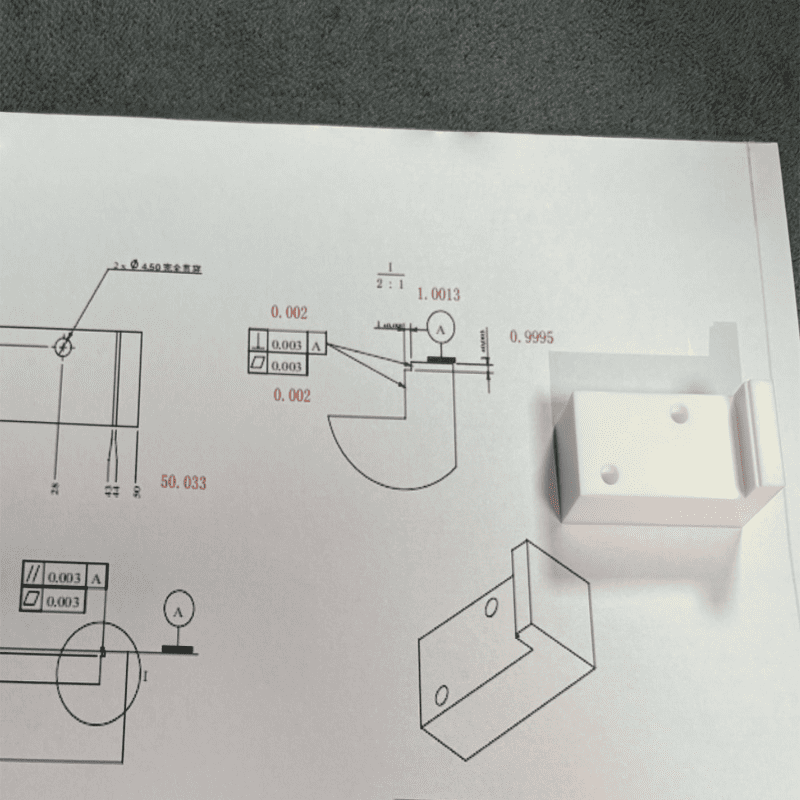

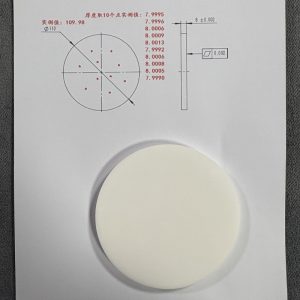

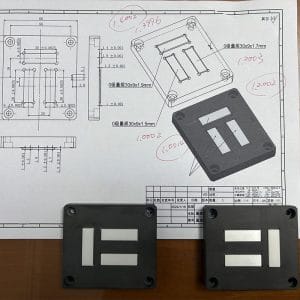

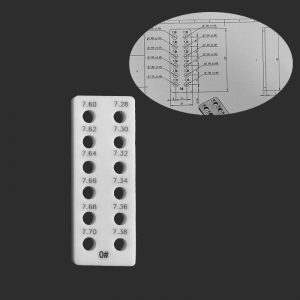

Recently, we have meticulously customized a batch of fixtures for a client in the electronics industry. In the precise production processes of electronics manufacturing, there is an extremely high demand for the accuracy of fixtures. According to the buyer’s requirements, the parallelism, flatness, and perpendicularity of these fixtures need to be controlled within ±0.003mm (3 microns) to ensure the precise positioning and operation of electronic components during processing.

Industrial ceramic is selected as the material for these fixtures. Thanks to its outstanding properties, industrial ceramic excels in accuracy, service life, and stability. It can maintain stable physical characteristics in complex electronics production environments, being less susceptible to factors such as temperature and humidity. This ensures that the accuracy does not deviate during long – term use and greatly extends the service life of the fixtures.

After processing, we conducted strict inspections on the fixtures. The surfaces of the parts are free from any defects such as scratches and abrasions, and all measured values meet the standards, fully complying with the client’s high – precision requirements.

The above – displayed content has been desensitized and does not involve commercial secrets. If you have confidentiality requirements, we can sign a confidentiality agreement to strictly protect your product information and will not disclose it to anyone. We are dedicated to providing customers with high – quality, high – precision customized fixture solutions, helping the electronics industry’s manufacturing reach new heights.