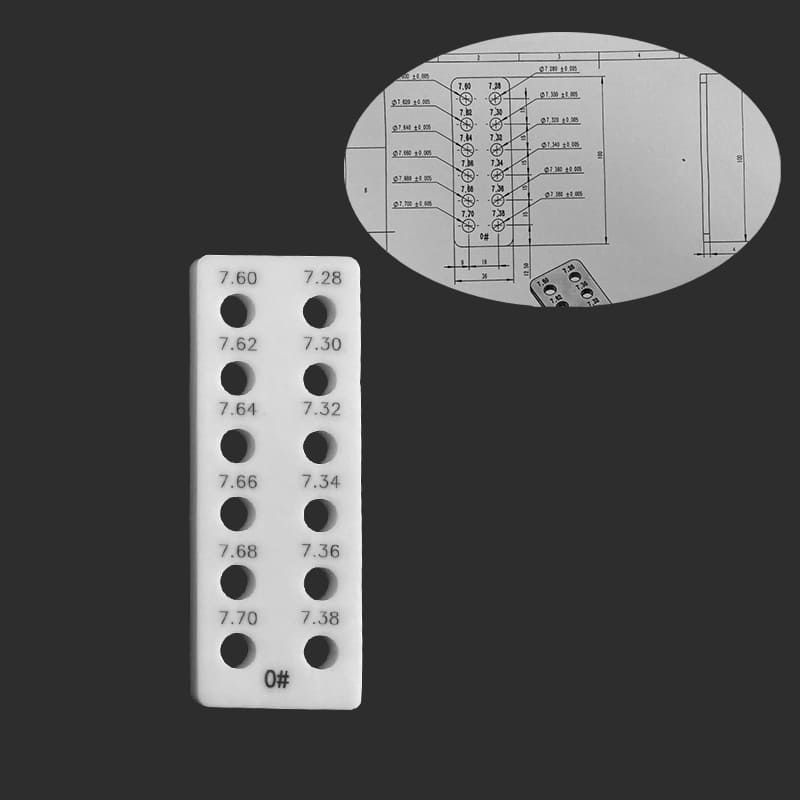

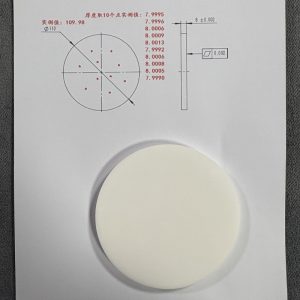

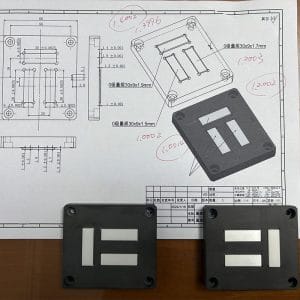

We have customized a batch of high – precision external diameter gauges for the medical industry, specifically designed for measuring the external diameter of objects. According to the buyer’s requirements, the diameter accuracy of the gauge holes needs to reach ±0.005 mm (5 microns) to ensure the accuracy and reliability of medical product measurements.

These gauges are made of industrial ceramic material, which has significant advantages in precision, service life, and stability. Industrial ceramics have excellent wear – resistance and corrosion – resistance, capable of maintaining long – term stability in complex medical environments and ensuring consistent measurement accuracy, meeting the strict requirements of the medical industry for measuring tools.

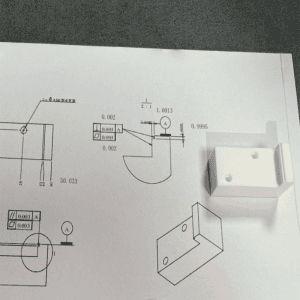

After the product is processed, the solid components have no deformation, and the surface is smooth without burrs. This not only improves the smoothness of the measurement process but also avoids potential damage to the measured medical components, fully reflecting the fineness and rigor of the craftsmanship.

The above – displayed content has been desensitized and does not involve commercial secrets. If you have confidentiality requirements, we can sign a confidentiality agreement to strictly protect your product information and will never disclose it to any third party. We are committed to providing customers with high – precision, high – quality customized measuring tool solutions with guaranteed information security, assisting the medical industry in precise measurement and escorting the quality of medical products.