High-Precision Zirconia Ceramic Calibration Block | Industrial Measurement Reference Solution

Ceramic Calibration Block • Ceramic Master Block • High-Precision Zirconia Ceramic Calibration Block

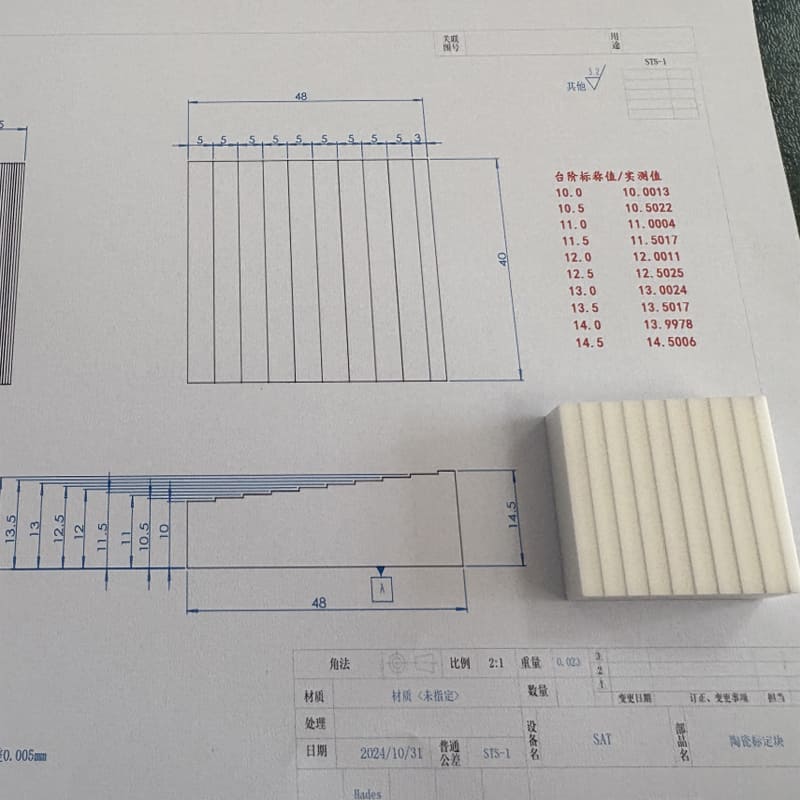

In semiconductor, aerospace, and precision manufacturing industries, measurement accuracy is the core of quality control. Our Zirconia Ceramic Calibration Block achieves a measured accuracy of ±0.003mm, exceeding the customer’s requirement of ±0.005mm. We can also customize ultra-high precision levels of ±0.001mm/±0.002mm, making it an ideal calibration reference for coordinate measuring machines (CMM) and optical inspection equipment to redefine industrial measurement benchmarks.

I. Core Parameters: Micron-Level Precision for Benchmark Quality

- Designed Accuracy: ±0.005mm (customized to customer requirements)

- Measured Accuracy: ±0.003mm (exceeding expectations, fully inspected by German Zoller laser detector)

- Material: Zirconia Ceramic (Y-TZP, hardness ≥1200HV, thermal expansion coefficient 9.6×10⁻⁶/℃)

Surface Quality: Ra≤0.02μm (mirror polishing), free of scratches or burrs, inspected under 100× electron microscope

II. Material Advantages: Disruptive Performance of Industrial Ceramics

1. Core Advantages of Zirconia Ceramic

| Performance | Zirconia Ceramic | Traditional Steel Calibration Block |

|---|---|---|

| Wear Resistance | 5× higher than steel | Prone to friction wear |

| Corrosion Resistance | Unaffected after 500 hours of medical alcohol immersion | Rusts after 300 hours |

| Thermal Stability | Size fluctuation ≤0.001% at -20℃~120℃ | Temperature-sensitive deformation |

| Biocompatibility | ISO 10993 certified | Requires additional coating |

| Environmental Friendliness | RoHS compliant, lead/mercury-free, 90%+ industrial waste recycled via regenerative technology | High energy consumption, complex waste disposal |

2. Structural Design Optimization

- Datum Surface Technology: Five-axis ultra-precision grinding ensures flatness/parallelism/perpendicularity tolerances ≤±0.003mm, meeting NIST traceability requirements;

- Lightweight Design: Density of only 6.0g/cm³, balanced center of gravity for handheld operation to reduce measurement fatigue errors.

III. Application Scenarios: Full-Industry Measurement Reference Solutions

1. Semiconductor & Electronics Manufacturing

- Calibrating 3D vision inspection equipment to ensure chip pin (0.1mm-level) positional accuracy;

Serving as a reference for LCD panel bonding machines to control micron-level gaps (e.g., OLED screen edge tolerances).

2. Aerospace Precision Machining

- Calibrating CMM for aerospace engine blade measurement, inspecting airfoil surface tolerances at ±0.005mm;

- Acting as a reference block for composite component (e.g., carbon fiber wing) hot-pressing molds to ensure dimensional stability in high-temperature environments.

3. Medical Device Manufacturing

- Verifying orthopedic implant (joint prosthesis) outer diameter measuring instruments, controlling ±0.005mm fit tolerances;

- ISO 10993 biocompatibility certified for long-term use in medical cleanroom environments.

IV. Quality Control: End-to-End Assurance from Production to Delivery

- Processing Technology: Three-stage process (rough grinding → fine grinding → mirror polishing), with single-piece processing time ≥8 hours;

- Inspection Standards: Compliant with ASME B89.1.9 (American Society of Mechanical Engineers gauge standards), optional authoritative calibration certificates available.

V. Customization Services: Tailored Measurement References

- Precision Upgrade: Support for ultra-high precision levels of ±0.001mm/±0.002mm (process lead time to be confirmed in advance);

- Marking Services: Laser-engraved customer logos, serial numbers, and precision parameters for traceability management.

VI. Confidentiality Commitment: Protecting Technical Assets

The above case studies are desensitized and do not involve customer technical details. For confidential projects, we offer:Legal Protection: Customizable Trade Secret Protection Agreements with clear liability clauses;

Elevate Your Measurement Accuracy Today

Whether calibrating CMMs, optical imaging systems, or establishing internal metrology standards, our Ceramic Calibration Block and Ceramic Master Block provide reliable references. Click to request a technical whitepaper or free sample test, and let precision become the core competency of your quality control.