About Us

We are located in Dongguan City, Guangdong Province, China, which is known as the world’s manufacturing hub.

Dongguan Dayou Precision Tools Co., Ltd. as a manufacturer of precision tools and measuring instruments with nearly 25 years of development experience, we have served and are still serving numerous customers from various industries, including but not limited to the electronic component industry, automation, medical, aerospace, robotics, university laboratories, and other fields.

A benchmark in global high-precision measuring tool manufacturing, with a detection accuracy of the 0.01μm level. The constant-temperature laboratory safeguards the commitment to quality.

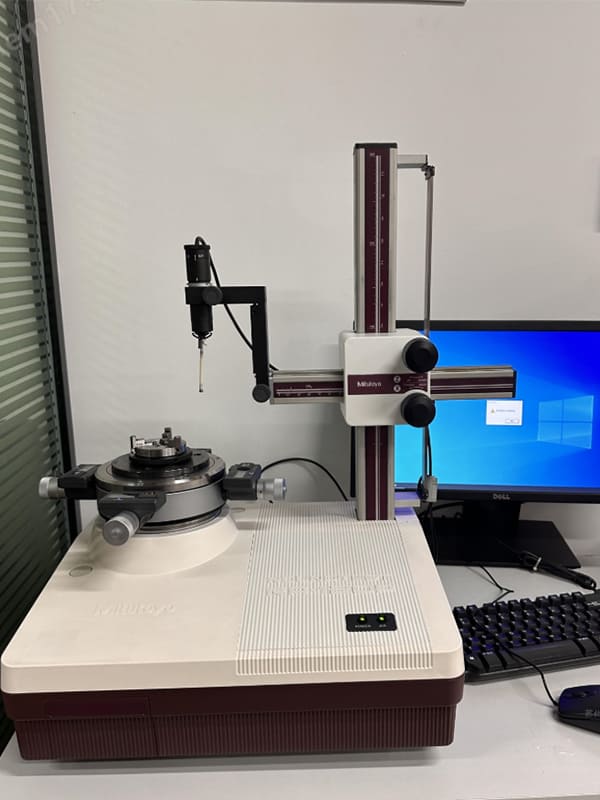

Cluster of cutting-edge inspection equipment.

Equipped with internationally leading devices such as the German Mahr coordinate measuring machine and Mitutoyo laser interferometer, it covers all-dimensional precision inspection needs including geometric quantities and form and position tolerances. It meets the certification requirements of international standard systems such as ISO and ASME, enabling ultra-micron level data collection and analysis of complex workpieces.

Environmental control with micron-level precision.

The laboratory maintains a constant temperature of 20 ± 0.5 °C throughout the year and a humidity level of 45%-55% RH. It is equipped with an independent air shower system and a three-stage air filtration device to eliminate the impact of environmental variables on the inspection results. The design of an ultra-silent and shock-proof foundation ensures the stable operation of nano-level measuring equipment.

A stringent quality control system throughout the entire process.

Implement a three-level quality inspection for “raw materials – semi-finished products – finished products”: spectral analysis of the hardness of raw materials, multi-dimensional verification of the form and position tolerances of semi-finished products, and re-inspection of the comprehensive accuracy of finished products. Each measuring tool is accompanied by a complete inspection report to ensure data traceability and compliance with international measuring tool calibration specifications.